Introduction to Mining Pipeline Challenges

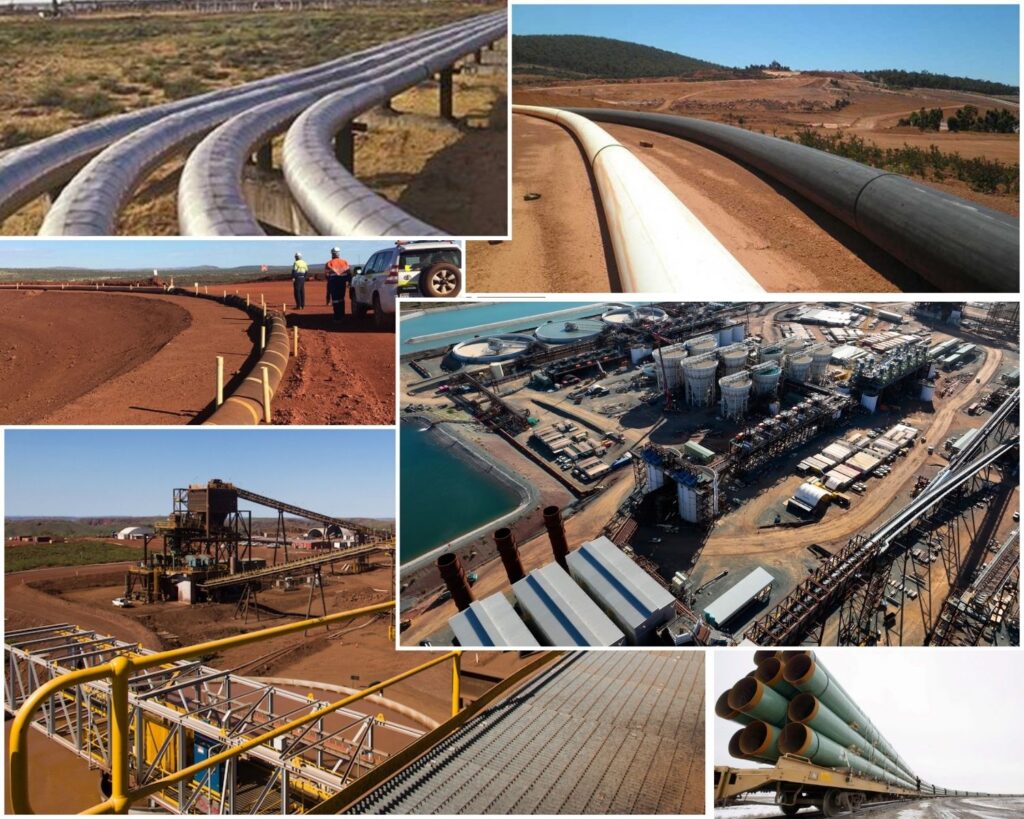

The mining industry heavily relies on pipelines for the transportation of essential resources, such as water, slurry, and various chemicals. These pipelines play a crucial role in ensuring the smooth operation of mining activities, from the extraction site to processing facilities and beyond. However, the industry faces numerous challenges when it comes to pipeline maintenance, efficiency, and reliability.Some of the common pipeline challenges in the mining sector include:

- Corrosion and wear due to harsh operating conditions

- Leaks and ruptures resulting in environmental damage and production losses

- Difficulty in accessing remote pipeline locations for maintenance

- Aging infrastructure leading to reduced efficiency and increased risk of failure

As the demand for mined resources continues to grow, it is essential to address these challenges head-on to ensure the industry’s long-term sustainability and profitability.

Historical Context and Evolution of Mining Pipelines

The use of pipelines in the mining industry dates back to the early 20th century, with the first recorded use of pipelines for transporting coal slurry in the United States. Over the years, pipeline technology has evolved significantly, with advancements in materials, construction methods, and monitoring systems.In the past, mining pipelines were primarily constructed using materials such as wood, cast iron, and steel. These materials were prone to corrosion, leaks, and structural failures, leading to frequent maintenance and replacement. To address these issues, the industry began experimenting with new materials, such as high-density polyethylene (HDPE) and fiberglass-reinforced plastic (FRP), which offered improved durability and corrosion resistance.Another significant development in the history of mining pipelines was the introduction of advanced monitoring and control systems. These systems allowed for real-time monitoring of pipeline performance, enabling operators to detect and address issues promptly. Some of the historical solutions to pipeline challenges included:

- Cathodic protection to prevent corrosion

- Regular inspection and maintenance programs

- Implementation of leak detection systems

- Use of corrosion-resistant coatings and linings

Despite these advancements, the mining industry continues to face pipeline challenges, particularly in terms of aging infrastructure and the need for more sustainable and environmentally friendly solutions.

Current State of Mining Pipeline Infrastructure

Australia’s existing mining pipeline networks face significant challenges in terms of capacity, efficiency, and aging infrastructure. Many pipelines were constructed decades ago and are now struggling to keep up with the increasing demands of the mining industry. Some key issues with the current pipeline infrastructure include:

- Insufficient capacity to transport growing volumes of resources like iron ore, coal, and LNG

- Corrosion and wear leading to leaks, ruptures, and unplanned downtime

- High operating costs due to inefficiencies and frequent maintenance requirements

- Difficulty accessing remote pipeline locations for repairs and upgrades

The economic impact of these pipeline inefficiencies is substantial. Unplanned outages disrupt mining operations, leading to lost production and revenues. High maintenance costs eat into profit margins. Bottlenecks in the pipeline network constrain the industry’s ability to capitalize on strong global demand for Australian resources. As an example, the Pilbara region in Western Australia is home to some of the world’s largest iron ore mines. However, the area’s aging pipeline infrastructure is increasingly seen as a limiting factor in plans to expand production capacity. Upgrades and expansions of the pipeline network will be critical to support the next phase of growth in Australia’s iron ore exports.

Technical Aspects of Pipeline Construction and Maintenance

Constructing and maintaining pipelines that can reliably transport mining outputs is a complex engineering challenge. The choice of materials, construction methods, and ongoing maintenance practices all play a crucial role in the long-term performance and integrity of a pipeline. Historically, mining pipelines were built using materials like wood, cast iron, and steel. However, these materials are prone to corrosion and structural failures, necessitating frequent repairs and replacement. In recent decades, there has been a shift towards more durable and corrosion-resistant options such as high-density polyethylene (HDPE) and fiberglass-reinforced plastic (FRP). Proper pipeline construction is essential to mitigate risks like leaks, ruptures, and environmental damage. Key steps in the construction process include:

- Surveying and site preparation

- Stringing and bending pipe segments

- Welding, testing, and coating pipe joints

- Trenching and lowering the pipeline

- Backfilling and site rehabilitation

Once a pipeline is operational, a robust maintenance program is critical to ensure ongoing safety and reliability. Common maintenance practices include:

- Regular inspection and testing using smart pigs and other methods

- Cathodic protection to prevent corrosion

- Timely repairs of any identified defects or damage

- Vegetation management to protect the pipeline right-of-way

Successful pipeline projects rely on meticulous design, high-quality construction, and proactive maintenance. A case study of the Australia Pacific LNG project highlights how innovative approaches like horizontal directional drilling can be used to minimise environmental impacts when crossing sensitive areas like rivers. As the mining industry grapples with the challenges posed by aging pipeline infrastructure, there is a clear need to invest in upgrades and expansions using the latest materials and construction methods. By adopting best practices in pipeline design, construction, and maintenance, mining companies can improve the efficiency and reliability of this critical transportation infrastructure.

Environmental Considerations and Sustainability

Mining pipelines pose significant environmental risks if not properly designed, constructed, and maintained. Leaks or ruptures can contaminate soil and water resources, harming ecosystems and potentially impacting human health. Some key environmental considerations for mining pipelines include:

- Water contamination: Pipeline leaks can introduce toxic chemicals and heavy metals into groundwater and surface water. This is especially concerning in areas with limited water resources

Soil contamination: Spills from pipelines can contaminate soil, making it unsuitable for plant growth and posing health risks to wildlife and humans.

Habitat fragmentation: Pipeline construction often requires clearing land, which can disrupt wildlife habitats and migration routes.

Greenhouse gas emissions: The energy-intensive processes involved in pipeline construction and operation contribute to a mine’s overall carbon footprint

To mitigate these risks, mining companies are increasingly adopting sustainable practices in pipeline development. Some examples include:

- Using more durable and corrosion-resistant materials like HDPE and FRP to reduce the likelihood of leaks

Implementing robust leak detection and rapid response systems to minimize the volume of any spills Utilizing trenchless construction methods like horizontal directional drilling to reduce surface disturbance Powering pipeline systems with renewable energy sources to cut greenhouse gas emissions

Effective environmental management requires a life-cycle approach, from the initial design and route selection to eventual decommissioning and site rehabilitation. Regular monitoring and maintenance are also critical to identify and address any issues promptly.

Regulatory Framework and Compliance Issues

Mining pipelines are subject to a complex web of regulations at the local, state/provincial, and national levels. These rules cover everything from construction standards and safety requirements to environmental protection and stakeholder consultation. In Australia, for example, key legislation includes:

- The Environmental Protection Act 1994, which requires environmental authorities for mining activities

- The Petroleum and Gas (Production and Safety) Act 2004, which sets out safety requirements for pipelines

- The Water Act 2000, which governs impacts on water resources

Compliance with this regulatory framework is essential to secure and maintain the necessary approvals for pipeline projects. Non-compliance can result in fines, operational restrictions, or even project cancellations. Some common compliance challenges for mining pipelines include:

- Navigating the complex and sometimes overlapping requirements of different regulatory agencies

Adapting to changes in regulations over the multi-decade lifespan of a pipeline Managing the expectations and concerns of local communities and other stakeholders. Demonstrating adequate environmental protection measures and emergency response plans To address these challenges, mining companies need to invest in robust compliance management systems. This includes dedicating resources to tracking regulatory changes, engaging proactively with regulators and stakeholders, and regularly auditing compliance performance. Transparency and accountability are also increasingly important in building trust with regulators and communities. Some companies are going beyond minimum compliance requirements by voluntarily adopting higher standards and reporting publicly on their environmental and social performance. As societal expectations around corporate responsibility continue to evolve, the regulatory framework for mining pipelines is likely to become even more stringent. Companies that can stay ahead of these trends and demonstrate leadership in sustainable practices will be best positioned for long-term success.

Innovations Addressing Mining Pipeline Challenges

The mining industry is continuously evolving, and innovations in pipeline technology are at the forefront of this transformation. These advancements aim to improve the efficiency, safety, and sustainability of pipeline operations, addressing many of the challenges faced by the industry.

Smart Pipeline Systems

One of the most promising innovations is the development of smart pipeline systems. These systems integrate advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics to provide real-time monitoring and predictive maintenance capabilities. By leveraging these technologies, operators can detect potential issues before they become critical, optimize pipeline performance, and reduce downtime.

Alternative Energy Transportation

With the global shift towards renewable energy, there is a growing need for pipelines capable of transporting alternative fuels like hydrogen and biofuels. Developing pipelines that can safely handle these substances at high pressures and over long distances presents unique challenges. However, innovative solutions are being explored to address these challenges, ensuring the safe and efficient transportation of alternative energy sources.

Environmental Impact Mitigation

As environmental concerns continue to rise, the focus on minimizing the ecological footprint of pipeline operations has intensified. Innovations in this area include the use of eco-friendly construction materials, advanced leak detection systems, and methods to reduce greenhouse gas emissions. These efforts are crucial for ensuring the sustainable development of pipeline infrastructure.

Case Studies of Successful Innovations

Several case studies highlight the successful implementation of innovative pipeline technologies. For instance, the use of horizontal directional drilling (HDD) in the Australia Pacific LNG project minimized environmental impacts while crossing sensitive areas like rivers. Another example is the integration of AI-driven risk management systems in mining operations, which has significantly improved safety and operational efficiency.

Economic Analysis: Cost-Benefit of Pipeline Investments

Investing in pipeline infrastructure is a significant financial commitment, but the potential benefits can far outweigh the costs. A thorough economic analysis is essential to understand the financial implications and return on investment (ROI) for pipeline upgrades and new installations.

Financial Implications of Pipeline Investments

The initial costs of pipeline construction and maintenance can be substantial. However, these investments are crucial for ensuring the long-term efficiency and reliability of mining operations. Key financial considerations include:

- Construction Costs: The expenses associated with materials, labor, and equipment for building new pipelines or upgrading existing ones.

- Maintenance Costs: Ongoing costs for regular inspections, repairs, and upgrades to maintain pipeline integrity and performance.

- Operational Costs: Expenses related to the day-to-day operation of pipelines, including energy consumption and monitoring systems.

Return on Investment (ROI)

Investing in modern pipeline infrastructure can yield significant returns by enhancing operational efficiency, reducing downtime, and minimizing environmental risks. Some of the key benefits include:

- Increased Productivity: Upgraded pipelines can handle higher capacities and operate more efficiently, leading to increased production and revenue.

- Reduced Maintenance Costs: Advanced materials and technologies can extend the lifespan of pipelines and reduce the frequency and cost of repairs.

- Environmental Compliance: Modern pipelines are designed to meet stringent environmental regulations, reducing the risk of fines and legal issues.

Cost-Benefit Analysis

A comprehensive cost-benefit analysis can help mining companies make informed decisions about pipeline investments. This analysis should consider both the direct financial benefits and the broader economic impacts, such as job creation and community development. By carefully evaluating the costs and benefits, companies can ensure that their investments in pipeline infrastructure deliver maximum value. In conclusion, the mining industry is poised for significant advancements in pipeline technology. By embracing innovations and conducting thorough economic analyses, mining companies can overcome existing challenges, improve operational efficiency, and contribute to a more sustainable future.

Innovations Addressing Mining Pipeline Challenges

The mining industry is constantly evolving, with cutting-edge technologies and innovative methods being developed to improve pipeline operations and address the challenges faced by the sector. Some of the most promising innovations include:

Smart Pigging: Advanced pipeline inspection gauges, or “smart pigs,” are being used to detect corrosion, leaks, and other defects in pipelines. These devices use a combination of ultrasonic, magnetic flux leakage, and other sensing technologies to provide detailed data on the condition of the pipeline

Fiber Optic Monitoring: Distributed fiber optic sensing systems can continuously monitor pipelines for temperature, strain, and acoustic anomalies, enabling early detection of leaks or other issues. This technology allows for real-time monitoring of the entire pipeline length, improving response times and minimizing potential damage.

Predictive Maintenance: Advanced data analytics and machine learning algorithms are being applied to pipeline monitoring data to predict potential failures before they occur. By identifying patterns and anomalies in the data, operators can proactively schedule maintenance and repairs, reducing downtime and extending the life of the pipeline.

Robotic Inspection: Autonomous robots equipped with cameras, sensors, and non-destructive testing equipment are being developed to inspect pipelines in hard-to-reach or hazardous locations. These robots can navigate through the pipeline, collecting data and performing repairs without the need for human intervention.

Trenchless Technologies: Innovations in trenchless pipeline construction, such as horizontal directional drilling and pipe ramming, are reducing the environmental impact and cost of pipeline installations. These methods allow for the installation of pipelines with minimal surface disturbance, reducing the need for extensive excavation and site rehabilitation

As the mining industry continues to face pipeline challenges, the adoption of these and other innovative technologies will be crucial in ensuring the safe, efficient, and sustainable operation of pipeline infrastructure.

Economic Analysis: Cost-Benefit of Pipeline Investments

Investing in pipeline infrastructure is a significant financial undertaking for mining companies, with far-reaching implications for their bottom line and overall competitiveness. A thorough economic analysis of the costs and benefits associated with pipeline investments is essential for making informed decisions and ensuring long-term profitability. Costs of Pipeline Investments:

Capital Expenditure: The initial cost of constructing a new pipeline or upgrading an existing one can be substantial, including expenses related to materials, labor, equipment, and land acquisition

Operating and Maintenance Costs: Once a pipeline is operational, ongoing costs include energy consumption, monitoring, inspection, repairs, and maintenance. These costs can vary depending on the age, condition, and complexity of the pipeline system. Environmental and Social Costs: Pipeline projects may incur additional costs related to environmental impact assessments, permitting, community engagement, and mitigation measures to address potential ecological and social risks

Benefits of Pipeline Investments:

Increased Production Capacity: Investing in new or expanded pipeline infrastructure can enable mining companies to transport larger volumes of resources, increasing their overall production capacity and revenue potential

Improved Operational Efficiency: Upgrading pipelines with advanced technologies, such as smart pigging and predictive maintenance, can enhance operational efficiency by reducing downtime, minimizing product loss, and extending the life of the infrastructure.

Reduced Transportation Costs: Pipelines offer a cost-effective alternative to other modes of transportation, such as trucking or rail, particularly for long-distance and high-volume transport of resources.

Enhanced Safety and Environmental Performance: Investing in pipeline integrity management and leak detection systems can help prevent accidents, minimize environmental impacts, and improve overall safety performance, reducing the risk of costly incidents and reputational damage

Return on Investment (ROI): The ROI for pipeline investments depends on various factors, including the scale of the project, the commodity being transported, market conditions, and the expected lifespan of the infrastructure. Mining companies must carefully evaluate the long-term financial viability of pipeline investments, considering potential risks and uncertainties. Successful pipeline investments require a comprehensive economic analysis that balances the upfront costs with the long-term benefits, while also accounting for environmental and social considerations. By making informed decisions based on robust financial models and risk assessments, mining companies can optimize their pipeline investments and secure a competitive advantage in the global market.

Risk Management and Mitigation Strategies

Mining pipelines are critical assets that require robust risk management and mitigation strategies to ensure their safe and efficient operation. Identifying potential risks and implementing effective mitigation measures can help prevent costly disruptions and environmental damage.

Identifying Potential Risks

Several risks are associated with mining pipelines, including:

- Corrosion: Pipelines are susceptible to corrosion due to exposure to harsh chemicals and environmental conditions. Corrosion can lead to leaks, ruptures, and structural failures

. Mechanical Damage: External forces, such as construction activities or natural disasters, can cause mechanical damage to pipelines, resulting in leaks or ruptures. Operational Risks: Human error, equipment failure, and inadequate maintenance practices can compromise pipeline integrity and performance. Environmental Risks: Leaks or spills from pipelines can contaminate soil and water resources, posing significant environmental and health risks

Mitigation Strategies

To mitigate these risks, mining companies can implement a range of strategies, including:

- Regular Inspections and Maintenance: Conducting regular inspections and maintenance can help identify and address potential issues before they become critical. Advanced technologies, such as smart pigs and remote monitoring systems, can enhance the effectiveness of these inspections

Corrosion Protection: Implementing corrosion protection measures, such as cathodic protection and the use of corrosion-resistant materials, can extend the lifespan of pipelines and reduce the risk of leaks and ruptures.

Emergency Response Plans: Developing and maintaining comprehensive emergency response plans can help minimize the impact of pipeline incidents. These plans should include procedures for leak detection, containment, and cleanup, as well as communication protocols with relevant stakeholders.

Training and Education: Providing ongoing training and education for pipeline operators and maintenance personnel can help ensure that they are equipped with the knowledge and skills needed to manage pipeline risks effectively

By implementing these risk management and mitigation strategies, mining companies can enhance the safety, reliability, and sustainability of their pipeline operations.

Conclusion: The Future of Mining Pipelines

The mining industry is at a critical juncture, with aging pipeline infrastructure and increasing environmental and regulatory pressures driving the need for innovative solutions. The future of mining pipelines will be shaped by advancements in technology, materials, and practices that enhance efficiency, safety, and sustainability.

Key Takeaways

- Technological Innovations: Cutting-edge technologies, such as smart pipeline systems, alternative energy transportation, and advanced environmental impact mitigation methods, will play a crucial role in addressing the challenges faced by mining pipelines

Economic Benefits: Investing in modern pipeline infrastructure can yield significant returns by improving operational efficiency, reducing maintenance costs, and ensuring compliance with environmental regulations.

Sustainability: Sustainable practices, such as the use of eco-friendly materials and renewable energy sources, will be essential for minimizing the environmental footprint of pipeline operations and ensuring long-term industry viability.

Regulatory Compliance: Navigating the complex regulatory landscape and maintaining compliance with evolving standards will be critical for securing the necessary approvals and maintaining stakeholder trust

Future Predictions

Looking ahead, the mining industry is likely to see continued advancements in pipeline technology and practices. Some potential future developments include:

- Increased Adoption of Trenchless Technologies: Trenchless methods, such as Cured-In-Place Pipe (CIPP) relining, will become more prevalent due to their cost-effectiveness, efficiency, and minimal environmental impact

Integration of AI and IoT: The integration of artificial intelligence (AI) and the Internet of Things (IoT) into pipeline monitoring and maintenance systems will enable more proactive and predictive management of pipeline assets.

Focus on Renewable Energy: As the global shift towards renewable energy continues, pipelines capable of transporting alternative fuels, such as hydrogen and biofuels, will become increasingly important

In conclusion, the future of mining pipelines will be defined by innovation, sustainability, and resilience. By embracing these principles, the mining industry can overcome existing challenges, capitalize on new opportunities, and ensure the safe, reliable, and sustainable transportation of resources for generations to come. This concludes the comprehensive article on “Cured in-place (CIPP) pipe relining for rehabilitation of stranded assets” for the Nexa Pipe company website. The content has been crafted to highlight the expertise and in-depth knowledge of the subject, ensuring readability and engagement for a broad audience.