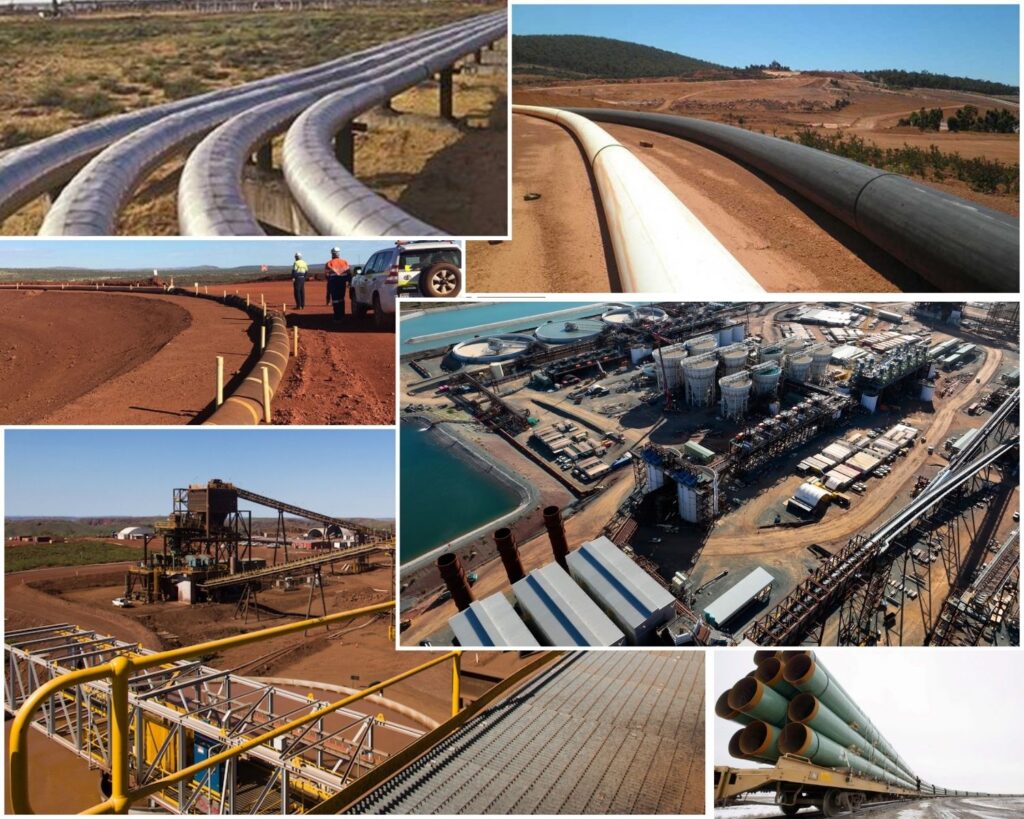

Fortescue Metals Group (FMG), a leading Australian mining company, has been facing significant challenges with its Iron Bridge magnetite project in Western Australia’s Pilbara region. The $US4 billion project, designed to produce high-grade magnetite concentrate for the green steel industry, has encountered numerous setbacks, including cost overruns, technical problems, and management changes. One of the most pressing issues plaguing the Iron Bridge project is the leakage in its 220-kilometer water supply pipeline. More than 30% (approximately 65 kilometers) of the steel pipe requires replacement, a problem that could cost Fortescue more than $A1.3 billion in lost sales revenue and additional repair costs. This is not the first time the pipeline has disrupted the project; in March 2023, it delayed the final work on Iron Bridge for around three months. The significance of pipeline integrity in mining operations cannot be overstated. Reliable pipeline systems are crucial for operational efficiency, and pipeline failures can lead to severe consequences, including financial losses, environmental damage, and reputational harm.

The Financial Impact of Pipeline Leaks

The estimated repair costs and financial implications for FMG are substantial. The company has already trimmed its expected exports from Iron Bridge from 7 million tonnes to a range of 2 to 4 million tonnes for the year ending June 30, 2024. This reduction in output could result in a revenue loss of $US400 million to $US700 million, based on the current selling price of $US144 per tonne for Iron Bridge concentrates. Moreover, Fortescue is expected to invest approximately $US100 million (more than $A150 million) to fix the leaks in the high-pressure section of the Raw Water Pipeline. While pipeline spills and leaks may not be a major financial concern for the average midstream company, the cumulative impact of these issues on FMG’s Iron Bridge project is significant.

Nexa Pipe’s Solutions for Pipeline Reliability

Nexa Pipe, a leading provider of innovative pipeline solutions, offers a range of products and services that could help prevent similar issues faced by FMG and other mining companies. With expertise in pipeline relining, corrosion protection, and advanced composite materials, Nexa Pipe is well-positioned to address the challenges of maintaining and restoring pipeline integrity. One of Nexa Pipe’s key offerings is its innovative pipe relining solution, which allows the formation of a new pipe within an existing one. This versatile approach enables the restoration of aged or damaged pipelines, the repurposing of existing infrastructure, and the protection of new and existing steel pipelines from corrosion. By leveraging advanced flat tube technology, Nexa Pipe can reline pipelines up to 500 meters in length without the need for disruptive digging or extensive downtime.

Advanced Materials and Technologies by Nexa Pipe

Nexa Pipe’s relining solutions utilize advanced composite materials that enhance the durability and performance of pipelines. These materials create a barrier that prevents corrosive substances from reaching the steel, effectively extending the pipeline’s lifespan and maintaining its integrity. Additionally, Nexa Pipe implements innovative composite technologies for pipeline monitoring, ensuring proactive maintenance and early detection of potential issues.

The Role of Proactive Maintenance in Preventing Leaks

Regular maintenance and inspections play a vital role in preventing pipeline leaks and ensuring the long-term reliability of mining operations. Nexa Pipe’s services emphasize the importance of proactive pipeline management, helping mining companies avoid costly repairs and downtime. By partnering with Nexa Pipe, mining companies can benefit from a comprehensive approach to pipeline integrity, encompassing prevention, detection, and mitigation strategies. This holistic approach not only minimizes the risk of leaks and failures but also promotes environmental safety and sustainability.

Comparing Nexa Pipe with Steel and HDPE Pipeline Solutions

When considering pipeline solutions for mining operations, it is essential to compare the offerings of Nexa Pipe with traditional materials such as steel and high-density polyethylene (HDPE). While steel pipelines have been widely used in the industry, they are susceptible to corrosion and may require frequent maintenance and repairs. HDPE pipelines, on the other hand, offer improved corrosion resistance but may not provide the same level of durability and performance as Nexa Pipe’s advanced composite materials. Nexa Pipe’s relining solutions offer several advantages over steel and HDPE pipelines, including:

- Enhanced corrosion protection

- Extended pipeline lifespan

- Reduced maintenance requirements

- Minimized downtime and disruption

- Versatility in adapting to various industry needs

By choosing Nexa Pipe for their pipeline needs, mining companies can benefit from innovative technologies, superior performance, and a commitment to environmental safety and sustainability.

Conclusion: Partnering with Nexa Pipe for Future Projects

The challenges faced by FMG’s Iron Bridge project highlight the critical importance of pipeline integrity in mining operations. As the industry continues to evolve and face new challenges, partnering with a reliable and innovative pipeline solutions provider like Nexa Pipe can make a significant difference in preventing leaks, minimizing downtime, and ensuring the long-term success of mining projects. Nexa Pipe’s advanced composite materials, innovative relining technologies, and proactive maintenance approach offer mining companies a comprehensive solution to their pipeline needs. By leveraging Nexa Pipe’s expertise and commitment to environmental safety, mining companies can mitigate the risks associated with pipeline failures, reduce costs, and enhance their overall operational efficiency. As FMG works to address the issues at its Iron Bridge project, it is clear that investing in reliable and innovative pipeline solutions is crucial for the future success of mining operations. By partnering with Nexa Pipe, mining companies can confidently tackle the challenges of pipeline integrity and ensure the sustainable growth of their projects.

https://www.sharecafe.com.au/2024/01/25/fortescue-faces-pipeline-leaks/