Revolutionising the Pipeline Industry with Innovative Solutions

NEXA Pipe solves pipe industry problems and enables Green Energy Transition

In-Factory and In-Field New Pipe Production

Discover NEXA Pipe’s innovative solutions in pipeline manufacturing, catering to diverse industries with versatile in-factory and in-field production capabilities. Learn how their state-of-the-art technology supports industries such as oil and gas, clean energy, mining, and more while promoting sustainability and efficiency. Explore NEXA Pipe’s commitment to developing cutting-edge solutions and transforming industries for a better, more sustainable future.

Pipe Relining and Rehabilitation

NEXA Pipe is revolutionising pipeline restoration with innovative relining solutions. Our advanced technology allows us to form a new pipe within an existing one, effectively extending its lifespan and functionality. Catering to diverse industries, we offer solutions for restoring aged pipelines, repurposing existing infrastructure, and protecting steel pipelines from corrosion. Join us in driving positive change towards a more sustainable and prosperous future.

Potential for Nexa Pipe on Australian and Global Pipe Market

Nexa Pipe is poised to revolutionize the pipeline industry in Australia and worldwide by leveraging its advanced composite pipe technology. With superior corrosion resistance, flexibility, strength, and durability compared to traditional pipe materials, Nexa Pipe can enhance pipeline safety, efficiency, and sustainability across critical industries.

Overcoming Pipeline Challenges with Composite Innovation

The mining, oil and gas, water, and energy industries face numerous challenges in constructing, maintaining, and operating pipeline infrastructure. Steel and HDPE pipes have limitations in terms of pressure ratings, temperature resistance, internal erosion, external corrosion, hydrogen embrittlement, and safety risks from leaks or ruptures. Nexa Pipe’s innovative composite pipe technology overcomes these issues through:

- Exceptional chemical and corrosion resistance to safely transport corrosive fluids

- Ability to withstand high temperatures and pressures without de-rating

- Lighter weight and flexibility for easier installation and seismic resilience

- Non-conductive properties to prevent lightning, stray current damage

- Low maintenance costs and long service life, reducing TCO

By leveraging these benefits, Nexa Pipe can enhance operational efficiency, safety, reliability, and sustainability for new and existing pipeline projects across Australia’s vital mining, oil and gas sectors.

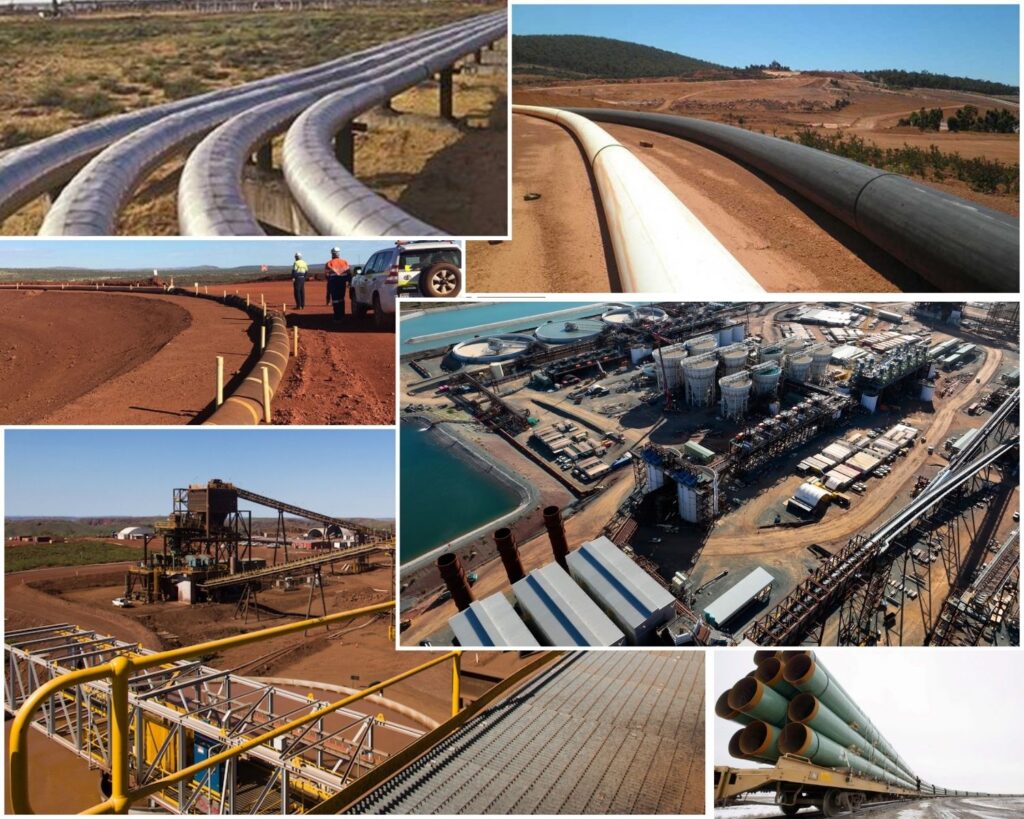

Positioned for Massive Growth in Australia

With the world’s largest lithium reserves, major iron ore and coal deposits, abundant gas and oil, and burgeoning renewable energy projects, Australia possesses tremendous pipeline infrastructure needs that Nexa Pipe is ideally positioned to serve, including:

- Iron ore slurry, water, and tailings pipelines

- Cross-country gas transmission pipelines

- Seawater pipelines for coastal gas plants

- Geothermal plant steam transport lines

- Hydrogen infrastructure build-out

- Water pipelines from desalination plants

- Brine disposal lines from lithium projects

Nexa Pipe’s solutions can also help Australia upgrade and maintain its aging pipeline infrastructure sustainably through trenchless relining technology to extend asset lifespan without disruptive replacement.

Global Potential Across Sectors

Beyond Australia, Nexa Pipe sees strong global potential across the following sectors:

Oil & Gas

- Shale oil/gas gathering and water lines

- Cross-country oil/gas transport

- Offshore production and transmission pipelines

- Oil pipelines with low temperature resilience

Mining

- Copper, lithium, and iron ore water and slurry pipelines

- Pipes transporting hazardous mining chemicals

- Tailings and wastewater management systems

Water

- Large scale water delivery and wastewater pipes

- Desalination plant seawater intakes and brine disposal

- Reducing water loss through enhanced leak prevention

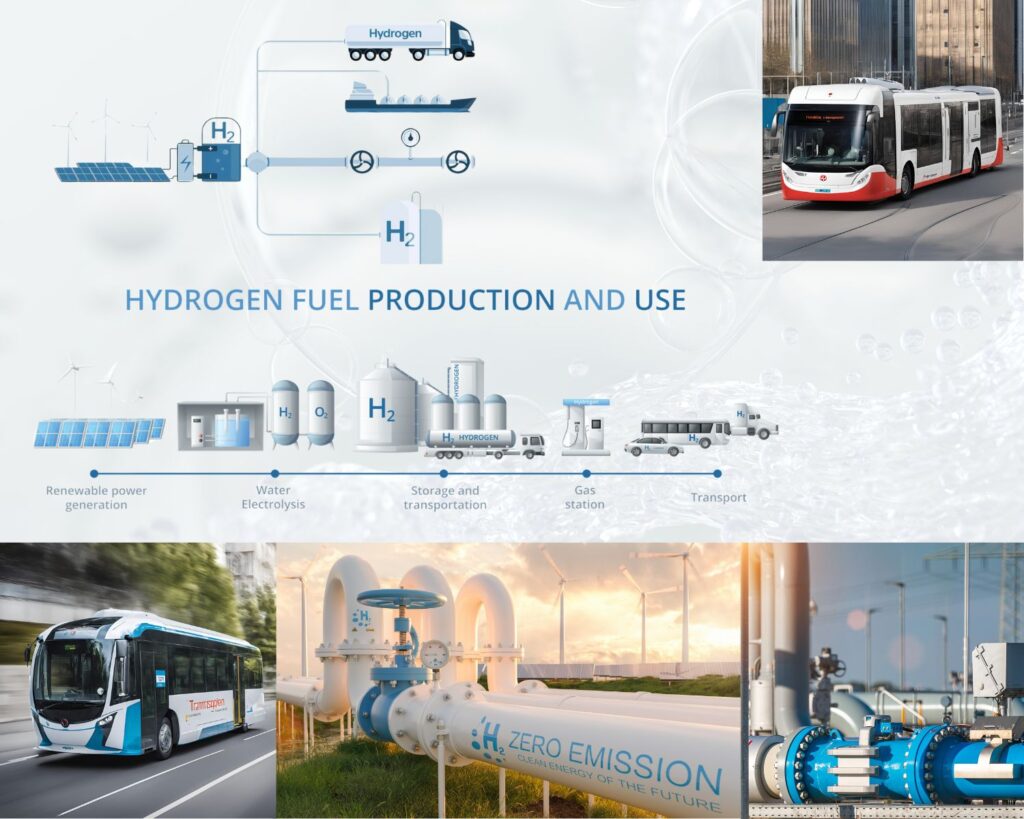

Clean Energy

- Hydrogen and ammonia pipelines for renewable energy

- CO2 transport lines for carbon capture projects

- Geothermal and solar thermal plant piping systems

Industrial

- District heating and cooling networks

- Thermal utility pipes at industrial parks and refineries

- Hazardous chemical transport pipes

This broad range of applications demonstrates the immense global potential for Nexa Pipe to set new performance benchmarks across industries.

With game-changing technology unlocking safety, efficiency and sustainability gains not possible with legacy materials, Nexa Pipe is poised for enormous growth in Australia and worldwide. By leveraging its innovative composite piping solutions, Nexa Pipe can become the new gold standard for pipelines across mining, oil and gas, water, energy, and industrial sectors. A bright future lies ahead.

Nexa Pipe’s value proposition:

- Provides superior corrosion resistance compared to traditional pipe materials like steel and HDPE. This enables safer transportation of corrosive fluids and gases.

- Can withstand much higher temperatures and pressures without de-rating (in comparison with HDPE and other plastic pipes). This allows higher throughput volumes and avoids capacity limitations.

- Lighter weight and flexibility enables easier installation, even in remote areas or rugged terrain. This reduces construction costs and environmental impact.

- Non-conductive properties prevent damage from lightning strikes and stray electrical currents.

- Thinner walls maximize internal diameter while retaining strength. This increases flow rates and efficiency.

- Trenchless relining technology can restore old pipelines without digging and disruption. This saves money and environmental impact.

- In-field manufacturing with 500m+ pipe lengths reduces number of joints. This minimizes leak risks, reduces construction costs and environmental impact.

- Long service lifetime with low maintenance requirements reduces total cost of ownership.

- Scalable manufacturing processes allow rapid capacity increases to serve growing demand.

- Customizable resin formulas enable optimization for specific fluid properties and operating conditions.

- Enables repurposing or enhancing existing pipelines for new uses like hydrogen or carbon transport.

Overall, Nexa Pipe can provide step-change improvements in pipeline safety, reliability, efficiency, and sustainability across industries compared to legacy pipe materials. Its solutions unlock strategic advantages and operational cost savings for owners and operators.

Contact us:

Challenges in Mining Pipelines

Introduction to Mining Pipeline Challenges The mining industry heavily relies on pipelines for the transportation…

Repurposing of oil and gas pipelines for new energy applications

Revolutionizing Pipeline Infrastructure: The Power of Repurposing In the face of the global energy transition,…

Revolutionising Hydrogen Transportation for a Sustainable Future

As a leading expert in pipeline solutions, Nexa Pipe is at the forefront of transforming…

Slurry Pipeline Challenges in the Mining Industry

Nexa Pipe understands the complexities and obstacles that mining operations face when it comes to…

Enabling the Future of Carbon Capture and Storage

Carbon storage The urgent need to mitigate climate change has spurred a global transition towards…

Enabling Singapore’s Hydrogen Pipeline Network

Hydrogen pipe The global transition towards clean energy has accelerated in recent years, with hydrogen…