Nexa Pipe understands the complexities and obstacles that mining operations face when it comes to slurry pipelines. These vital arteries play a crucial role in transporting mineral-rich slurries, but they also present a unique set of challenges that demand innovative solutions. Let’s delve into the key hurdles and explore how Nexa Pipe’s cutting-edge technology is revolutionising the way the mining industry approaches slurry pipeline infrastructure.

Corrosion and Erosion: A Relentless Assault

Mineral slurries are inherently aggressive, often containing corrosive substances that can rapidly degrade traditional pipeline materials like carbon steel. This unrelenting assault leads to failures, leaks, and compromised structural integrity, posing significant risks to operations and the environment. 1 Moreover, the abrasive particles within the slurry act like sandpaper, gradually eroding the inner surfaces of pipelines over time. This wear and tear reduces wall thickness, further weakening the pipeline’s structural integrity and increasing the likelihood of catastrophic failures.

Clogging and Blockages: Disrupting Smooth Operations

The accumulation, settling, or deposition of solid particles within slurry pipelines can lead to clogging and blockages, disrupting normal operations and potentially damaging equipment. These obstructions not only impede the flow of slurries but also increase the risk of pipeline ruptures and spills. Additionally, insufficient pipeline velocity can result in a gradual buildup of deposits on the pipe walls, known as “growth rings” or “bottom scale.” These formations further restrict flow and exacerbate the risk of blockages, creating a vicious cycle that demands constant monitoring and maintenance.

Leakage from Damaged Seals: Compromising Safety and Performance

The high-pressure and abrasive nature of slurry transport can take a toll on the internal sealing systems of pumps and valves. Damaged components within these critical components can lead to leakage, impairing performance, impacting the working environment, and compromising safety for personnel and equipment.

High Energy Consumption: Draining Resources

Slurry pumps require substantial energy to operate, and inefficient pump selection or suboptimal operating conditions can significantly increase energy usage and costs. This not only impacts the bottom line but also contributes to a larger environmental footprint, making energy efficiency a crucial consideration for sustainable mining operations.

Frequent Maintenance Requirements: Costly Downtime

The harsh conditions and wear and tear associated with slurry pipelines necessitate frequent component replacements, cleaning, and repairs to maintain operational integrity. These maintenance requirements result in high costs and significant downtime, impacting productivity and profitability.

Environmental Impact of Spills: A Lasting Legacy

Perhaps one of the most significant concerns surrounding slurry pipelines is the potential for catastrophic failures that can release large volumes of slurry into the surrounding land and waterways. The cleanup and remediation of such spills are not only difficult and costly but can also have long-lasting environmental consequences, making spill prevention a top priority for responsible mining operations.

Nexa Pipe: Revolutionizing Slurry Pipeline Infrastructure

While traditional pipeline materials like steel and HDPE have their limitations, Nexa Pipe’s innovative composite pipe technology overcomes these challenges through exceptional corrosion resistance, abrasion resistance, and overall durability. By addressing the root causes of pipeline degradation, Nexa Pipe offers a comprehensive solution that enhances operational efficiency, safety, reliability, and sustainability for new and existing pipeline projects across Australia’s vital mining sectors.

Unparalleled Corrosion Resistance

Nexa Pipe’s advanced composite construction is impervious to the corrosive substances found in mineral slurries, eliminating the risk of material degradation and pipeline failures due to corrosion. This unparalleled corrosion resistance ensures a longer service life and reduced maintenance requirements, translating to lower total cost of ownership for mining operations.

Abrasion and Erosion: Withstanding the Wear and Tear

The smooth, non-metallic inner surface of Nexa Pipe is highly resistant to the abrasive effects of slurry flow, minimizing erosion and maintaining structural integrity over time. This exceptional durability ensures consistent performance and reduces the need for frequent replacements, further contributing to cost savings and minimizing downtime.

Lightweight and Flexible Design

Nexa Pipe’s lightweight and flexible design offers significant advantages over traditional pipeline materials. Its ease of installation and transportation reduces logistical challenges and associated costs, making it an attractive choice for remote mining locations. Additionally, its flexibility allows for more efficient routing and accommodates ground movements, reducing the risk of failures due to environmental factors.

Streamlined Flow and Reduced Clogging

The smooth inner surface of Nexa Pipe promotes streamlined flow and minimizes the accumulation of deposits, reducing the risk of clogging and blockages. This not only enhances operational efficiency but also reduces the need for frequent cleaning and maintenance, further contributing to cost savings and minimizing downtime.

Leak-Free Performance and Enhanced Safety

Nexa Pipe’s advanced sealing systems and leak-free design ensure reliable performance and enhanced safety for personnel and equipment. By eliminating the risk of leaks, mining operations can maintain a secure working environment and minimize the potential for environmental contamination.

Energy Efficiency and Cost Savings

The smooth inner surface of Nexa Pipe reduces friction and turbulence, resulting in improved flow characteristics and lower energy requirements for pumping operations. This translates to significant energy cost savings and a reduced environmental footprint, aligning with the mining industry’s sustainability goals.

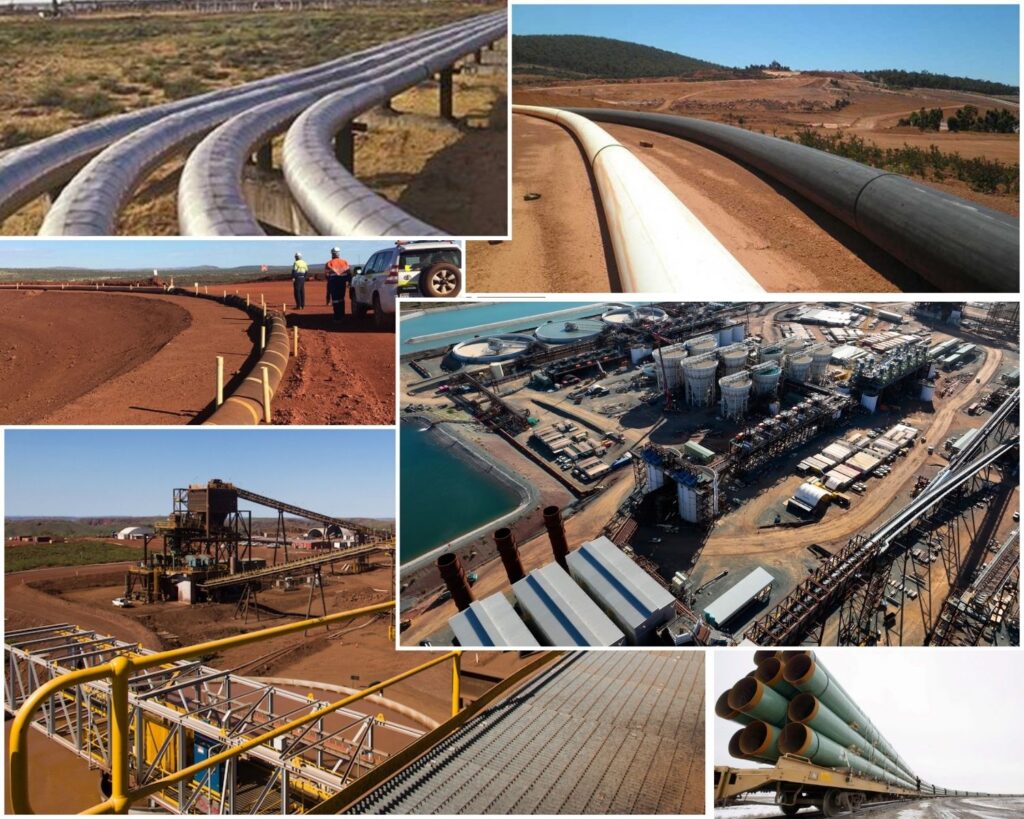

Positioned for Massive Growth in Australia

With the world’s largest lithium reserves, major iron ore and coal deposits, abundant gas and oil, and burgeoning renewable energy projects, Australia possesses tremendous pipeline infrastructure needs that Nexa Pipe is ideally positioned to serve. From copper, lithium, and iron ore water and slurry pipelines to pipes transporting hazardous mining chemicals, tailings, and wastewater management systems, Nexa Pipe offers a comprehensive range of solutions tailored to the unique challenges of the Australian mining industry.

A Sustainable Future for Slurry Pipeline Infrastructure

As the mining industry continues to evolve and face increasing environmental and regulatory pressures, the need for sustainable and reliable slurry pipeline infrastructure becomes paramount. Nexa Pipe’s commitment to innovation and its cutting-edge composite pipe technology position the company as a leader in this space, offering mining operations a solution that addresses the key challenges while promoting operational excellence, cost-effectiveness, and environmental stewardship. By partnering with Nexa Pipe, mining companies can benefit from:

- Reduced maintenance costs and downtime

- Improved safety for personnel and equipment

- Lower transportation and installation costs

- Increased overall efficiency and productivity

- Minimized environmental impact and enhanced sustainability

Don’t let the challenges of slurry pipelines hold your mining operations back. Embrace the future of pipeline infrastructure with Nexa Pipe and experience the transformative power of innovative composite pipe technology.

| Benefit | Traditional Pipelines: Steel/HDPE | Nexa Pipe |

|---|---|---|

| Corrosion Resistance | Limited resistance, susceptible to corrosion | Exceptional corrosion resistance |

| Abrasion Resistance | Prone to erosion and wear | Highly resistant to abrasive slurries |

| Leak Prevention | Potential for leaks and failures | Leak-free design and advanced sealing |

| Energy Efficiency | Higher friction and turbulence | Smooth inner surface for improved flow |

| Maintenance Requirements | Frequent replacements and repairs | Reduced maintenance and extended service life |

| Environmental Impact | Risk of spills and contamination | Minimized environmental footprint |

With a global network of resources and extensive experience in composite materials development and process engineering, Nexa Pipe is uniquely positioned to help mining companies revolutionize their slurry pipeline operations. Explore our innovative solutions today and unlock a future of enhanced efficiency, sustainability, and profitability for your mining endeavors.